2024.11.14

Hello everyone.

Today, I’ll be talking about the traditional style of knife known as a blacksmith knife.

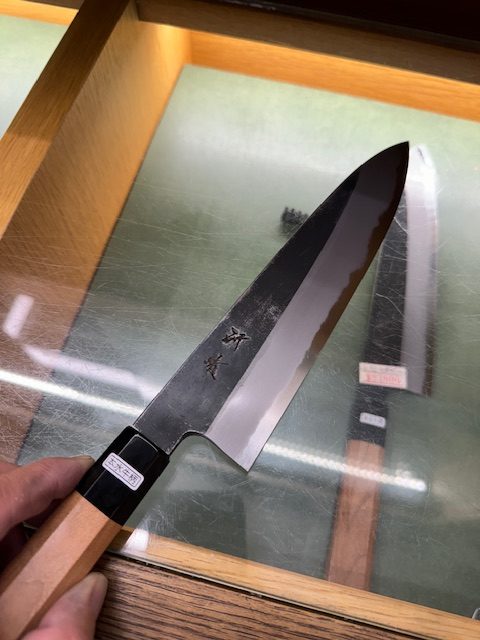

The knife shown in the photo is sold at our shop.

It is a Shirogami #2 (White Steel #2) Wagyuto (Japanese-handled chef’s knife) with a blacksmith finish. The blade is 210 mm long and has a cherry wood handle. The knife was made by the Togashi Knife Forging Workshop.

As you can see, the surface of the knife has a black finish.

This is known as blacksmith finish in the knife industry.

Blacksmith finish is achieved through a time-honored Japanese sharpening process.

The decorative characteristics of blacksmith are often used on forged knives.

Knives that are forged and quenched (heated to high temperatures and then rapidly cooled) turn black due to surface oxidation, as shown in the photo.

The technique of intentionally leaving the black oxidized area and sharpening only the blade is called blacksmith.

This technique exists because it offers several benefits.

1) It makes sharpening simpler for craftsmen, thereby reducing costs and resulting in reasonable product prices.

2) The oxidized parts are more resistant to rust (in a way, oxidation is already a form of rust). This makes the knives resistant to further rust.

In the past, the blacksmith finish was mainly used for Nakiri (vegetable knives) and Deba (butchering knives).

This was because these knives were used behind the scenes and out of sight of customers, so it was fine to omit decorative details from the knives.

Moreover, tool buyers were able to purchase high-quality knives at lower than normal prices.

Blacksmith knives were created to meet such needs.

However, this view of blacksmith knives is now a thing of the past.

Today, many overseas customers are interested in purchasing traditional Japanese knives.

To these customers, the blacksmith finish has a unique roughness and a handmade feel, making it popular as a traditional Japanese design.

It was people abroad who led a reevaluation of blacksmith knives’ value, something Japanese people had not recognized.

In fact, the blacksmith finish used on modern knives is even more beautiful than older knives.

Chemicals are used to evenly corrode the blade surface, thereby achieving a uniform black color and an even finer finish.

In fact, blacksmith knives may now take even more time than a standard finish created by polishing the entire blade.

In this way, the blacksmith finish, which was originally used to save effort by craftsmen, has been reborn as a highly skilled decorative technique that expresses the traditional beauty of knives.

Blacksmith knives and other Japanese knives will continue to evolve to meet the increasingly diverse demands of the market.

I hope you found this feature informative. I’ll see you next time!

Yosuke Kamata

Fourth-generation owner of Kamata Hakensha (specialty knife shop on Kappabashi Dougu Street)

What is a Honyaki (Single Steel Knife)? An easy-to-understand explanation of characteristics, manufacturing method, and price of the pinnacle of Japanese knives

https://www.kap-kam.com/en/blog/honyaki-the-king-of-japanese-knives/

© 2022 Kamata Hakensha All Rights Reserved.